- info@throop.com

- + 800-796-0285

Rapid Set® Cement makes our rapid concrete repairs, and all of the benefits that come with that, possible. Compared to Portland Cement, Rapid Set concrete gains strength faster, is more resistant to freeze/thaw cycles, resists sulfate attack better, experiences almost no shrinkage during hydration, and, due to all of these advantages, is far more durable than Portland Cement.

Rapid Set® Cement makes our rapid concrete repairs, and all of the benefits that come with that, possible. Compared to Portland Cement, Rapid Set concrete gains strength faster, is more resistant to freeze/thaw cycles, resists sulfate attack better, experiences almost no shrinkage during hydration, and, due to all of these advantages, is far more durable than Portland Cement.

Due to its rapid hardening qualities, working with Rapid Set Cement requires specialized equipment and a level of expertise and training that most companies simply do not have. Throop, however, is your solution provider. We have been working with Rapid Set since 1990. Every year, our project managers attend training specific to working with Rapid Set Cement. In addition to our skills, we have the specialized custom-designed equipment to produce the concrete fresh and immediately on the job site.

The Throop Company has the experience, expertise, and the equipment to handle any concrete production job. We were the first Certified Rapid Set Concrete producer in the United States. We have more years of experience using Rapid Set concrete than any of our competitors.

Rapid Set cement is a type of cement that is used for special purposes when a faster rate of early high strength is required.

The Volumetric Concrete Mixer is the best mixing method to produce Rapid Set cement concrete.

Rapid Set is especially manufactured to bring components together in a certain way so that they come to strength within an hour. This fast setting concrete is used in repair work which is urgent and when concreting in cold weather. It has proven itself over and over again in places where quick repairs are required such as airfield and highway pavements, retail stores, marine structures, bridge decks, and refrigerated rooms cooler than 45 oF. Rapid Set, time and time again, delivers a superior concrete.

Rapid Set cement is classified as a Rapid Hardening Cement that meets ASTM C150 and C1 157 specifications and more.

The George L. Throop Company uses many different cement mix designs and grouts. Our expertise is in producing fast setting concrete in large or small quantities.

Rapid Set has the following features:

- Gains structural strength in 1.5 hours — you can drive on this concrete after it has been placed in a little over 1

hour

hour - Drying shrinkage is reduced

- Reduces porosity

- When Rapid Set concrete is produced on-site there is no waste

- Mix designs can be created for all applications

- Pump mixes

- Interior or exterior applications

- Apply flooring, tile or coating in 8 hours or less

Rapid Set Cement has 6 advantages over regular Portland Cement:

- Rapid Set is fast!

- Rapid Set Cement sets within 45 minutes.

- Rapid Set Cement obtains structural strength (3000 PSI) in 1.5 hours or less.

- Rapid Set Cement achieves flexural strength (550 PSI) in 2 hours or less.

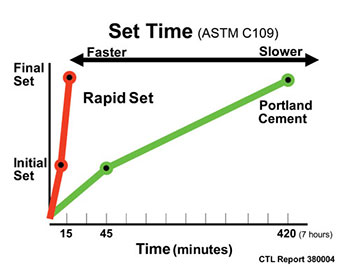

- View the chart on the right displaying the differences in Set Time between Portland Cement and Rapid Set Cement

- Rapid Set has a better Compressive Strength than Fast Track Portland or regular Portland Cement.

- Rapid Set reaches Flexural Strength (ASTM C1157) faster than required

- Freeze/thaw resistance of Rapid Set greatly surpasses Portland Cements.

- Rapid Set concrete resists sulfate attack far more effectively than Regular Portland Cement concrete.

- Rapid Set has as little as ¼ the shrinkage of regular Portland cement in addition to having lower porosity as Regular Portland Cement.

- This fast setting concrete is far more durable than regular Portland cement concrete. Through strict testing it was determined that Rapid Set Cement concrete expected fatigue life is approximately 87 years.

- Using Rapid Set Cement concrete saves you money – it can be a lot too.

- Due to Rapid Set cement’s fast strength gain, work crews can double its productivity.

- Double the productivity and you’ve just cut your labor costs and equipment rental costs in half.

Rapid Set was developed to meet three important criteria:

- Gain structural strength in 1.5 hours after placement

- Materially reduce drying shrinkage

- Reduce porosity

Workable 5″ slump Rapid Set Cement concrete gains compressive strength of 2500 to 3000 psi in 1.5 hours. The shrinkage of Rapid Set Cement is about 25% of the shrinkage of same slump Portland Cement concrete.

The porosity of Rapid Set Cement is much lower than Portland Cement. This improved durability is demonstrated by superior freeze thaw resistance. When tested by ASTM 666 method, PCC fails within 350 cycles of freezing and thawing. Rapid Set Cement is good for 1000 cycles. Also the chloride ion penetration test shows Rapid Set Cement to have very low permeability. When latex is added to Rapid Set Cement, the coulomb rating is in single digits vs. rating of 500+ for Portland Cement.

Why Does Rapid Set Cement Perform So Well?

The chemical formulation of Rapid Set cement is such that the mixing water required for the workability is used in the hydration of the cement. In Portland cement, the water required for workability exceeds the water required for hydration. As this excess water leaves the concrete, it causes drying shrinkage and leaves voids.

Chemically, the Rapid Set cement is about 1/3 calcium sulfoaluminate (C4A3S) and 2/3 dicalcium silicate (C2S). Little if any tricalcium aluminate (C3A) or tricalcium silicate (C3S) are found in Rapid Set cement. By eliminating C3A, the sulphate resistance of Rapid Set cement is superior to even Type V sulphate resistant Portland cement. The elimination of C3S improves the durability of Rapid Set Cement.

To make most concrete sufficiently fluid for placement, a water to cement ratio (w/c) of about 0.45 is required, which is 45 pounds of water for 100 pounds of cement.

Portland cement requires a w/c of about 0.25 to hydrate the cement – 25 pounds of water for 100 pounds of cement, leaving an excess of 20 pounds of water for each 100 pounds of cement, resulting in voids and shrinkage in the concrete as the excess water leaves.

In Rapid Set cement the unique chemical compound C4A3S requires about 5 times more water to hydrate than the main compounds in Portland cement. This results in a w/c of about 0.45 to hydrate the cement – 45 pounds of water for 100 pounds of cement, leaving little excess water. This results in almost no shrinkage or voids.

Retarders are used to extend setting time. Rapid Set cement has a setting time of about 15 minutes at 70° F. Cooler temperatures extend the setting time and warmer temperatures shorten it. With retarders, the setting time may be extended to give adequate working time.

Super plastercisers work with Rapid Set Cement in much the same way they do with Portland cement. Most super plastercisers have a maximum effective life of about one hour after dosage.

How is Rapid Set Cement Tested?

It is tested by the same ASTM methods used in testing Portland cements (ASTM C 109). A water cement ratio of 0.43 is used in the test.

It is tested by the same ASTM methods used in testing Portland cements (ASTM C 109). A water cement ratio of 0.43 is used in the test.

Proportioning, Mixing, Placing, Finishing, and Curing of Rapid Set Concrete

The George L. Throop Company has the equipment, labor, and experience to produce Rapid Set concrete on-site up to 50 cubic yards per hour.

Generally, the mix designs for Rapid Set Cement are about the same as for Portland cement concrete. Rapid Set Cement may be substituted on a pound for pound basis for Portland cement.

Mixing and placing are the same as for Portland cement. Rapid Set Cement is generally placed at a 4″ to 6″ slump.

George L. Throop Company has the equipment and personnel to pump fresh Rapid Set concrete up to 400 feet.

Mixing and placing are the same as for Finishing of Rapid Set Cement can be different than Portland Cement. Rapid Set Cement has very little, if any, bleed water. The mixing water is quickly taken up in the hydration process. The time-honored troweling to “close it up” is not applicable to Rapid Set Cement. Often the desired finish can be achieved with a vibrating screed and brooming or tinning. A smooth steel trowel finish can be achieved with Rapid Set Cement.

Generally Rapid Set Cement needs added water on the top surface to make up for water lost to evaporation. A water spray for 1 to 2 hours after placement is usually adequate; the top surface should be wetted to maintain a sheen and the surface should not turn dull. When water curing is not practical, curing compounds may be used. Rapid Set Cement is susceptible to plastic shrinkage cracking in the same way PCC is, and the same precautions to prevent it should be used.

The color of Rapid Set Cement is generally lighter than PCC due to low iron in the cement. Oxide pigments can be added to create the desired architectural color.

Flooring or coatings may be applied to Rapid Set Concrete within 8 hours or less.

Where is Rapid Set Used?

Rapid Set Cement can replace Portland Cement in any application for which Portland Cement is used including airport and highway paving, bridge deck repairs and overlays, and repair of almost any concrete. Rapid Set Cement has been in use since 1982 with outstanding results when handled by experts. Many state highway departments and cities use Rapid Set Cement for their rehabilitation and repair work. Recently Caltrans used 25,000 cubic yards of Rapid Set Cement on the I-10 Pomona Pavement Replacement project. Also, 35,000 cubic yards of Rapid Set Cement were used in 1991-1995 for the replacement and rehabilitation of the Sea-Tac Airport 18 inch thick runway and taxiway pavement.

Although the cost of Rapid Set Cement costs more than Portland Cement the costs savings in time and equipment rental can make it well worth the price comparison.